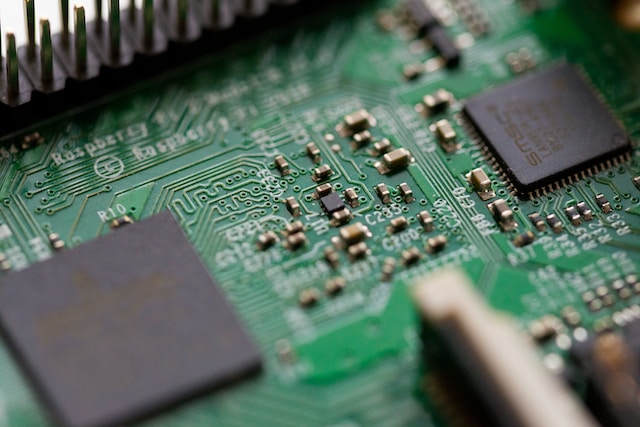

Electronic equipment

Vibration testing plays an increasingly important role in all stages of the automotive manufacturing industry. Most electronic products are required to work in a vibrating environment, and the damage caused by vibration to electronic products is mainly related to the dynamic characteristics of the product and its dynamic response during the vibration process.

Electronic products in some vibration frequencies will produce resonance, its amplitude is increasingly large, and finally due to vibration amplitude exceeds the product limit value and make electronic products damage. Or the product may be damaged by fatigue due to the long-term effects of stress caused by vibration acceleration. Regardless of the cause of product damage, the end result will lead to the failure of electronic products, thus causing the whole set of equipment failure, can not work properly.

Vibration testing of electronic products is easy to carry out and the test conditions are easily controlled. By simulating the vibration environment of a vehicle in transit and in operation, the durability and reliability of materials and components can be verified and design defects can be identified in advance for improvement. The characteristics of random vibration during transport are mainly from the road and tyres, while the characteristics of sinusoidal vibration are mainly from the engine, drive power and body vibration. Therefore, the vibration test methods in the standards currently used in the automotive industry are mainly focused on sinusoidal and random vibration.